Atreverse o no atreverse Taiichi Ohno

The 7 wastes are Taiichi Ohno's categorization of the seven major wastes typically found in mass production: Overproduction: Producing ahead of what's actually needed by the next process or customer. The worst form of waste because it contributes to the other six.

Taiichi Ohno, Lean Management Sensei and His Tools Lean Six Sigma Belgium

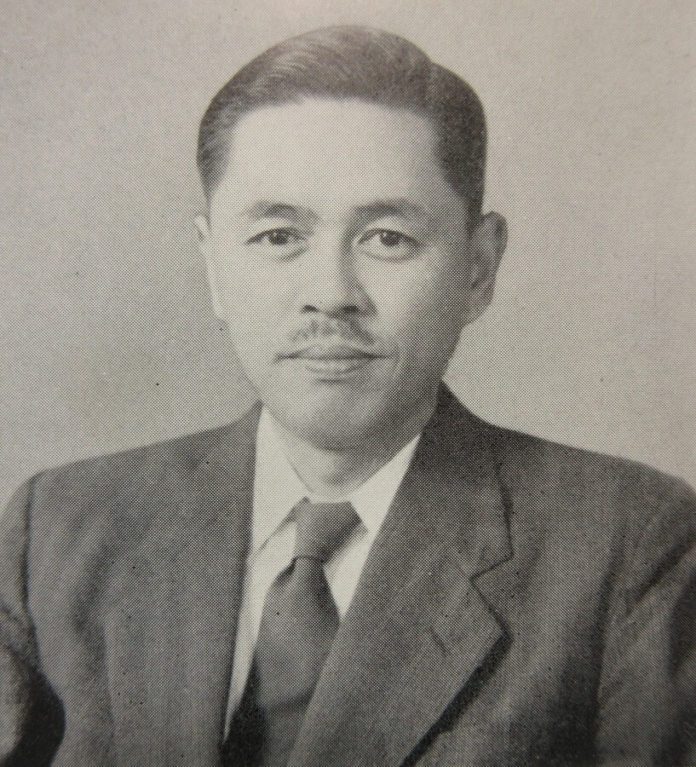

Taiichi Ohno (1912-1990) is not so much a guru but more a symbol of Japan's manufacturing resurgence after the second world war. Born in Dalian, in eastern China, he joined Toyota Automatic Loom.

Taiichi Ohno Interview Video Footage Gemba Academy

Taiichi Ohno Inducted 2022 1912 - 1990 Taiichi Ohno, an engineer and former Toyota executive, conceived and launched the fabled Toyota Production System (TPS). TPS facilitates the production of high-quality goods in the quickest and most efficient way possible.

Toyotismo historia, características, ventajas y desventajas

Ohno Taiichi (born 1912, Manchuria, China—died May 28, 1990, Toyota City, Japan) was a Japanese production-control expert for the Toyota Motor Co. His just-in-time system ( kanban) revolutionized manufacturing methods.

Taichii Ohno Lean Thinking bagi Wirausahawan

As Kiichiro Toyoda, Taiichi Ohno, and others at Toyota looked at this situation in the 1930s, and more intensely just after World War II, it occurred to them that a series of simple innovations might make it more possible to provide both continuity in process flow and a wide variety in product offerings.

ACAVIR Pensamiento Lean

Taiichi Ohno (February 29, 1912 - May 28, 1990) was an industrial engineer and manager at Toyota Motor Corporation. He joined the Toyoda Spinning corporation in 1932, and moved to the motor company in 1943. He started a a shop-floor supervisor, and eventually rose up to the executive level.

Costs do not exist to be calculated. Costs exist to be...

Taiichi Ohno was born in Manchuria, China in 1912 and graduated from Nagoya Institute of Technology. He joined Toyota in 1932 and for about twenty years worked his way up in the firm. In the 1940's and early 1950's, Ohno was the assembly manager for Toyota and developed many improvements that eventually became the Toyota Production System..

Identificando, combatendo e eliminando as oito fontes de desperdícios

Ohno, then an executive, was entrusted with the task of revitalizing the company. Hisashi Noguchi, who interviewed Ohno multiple times, shares a comment in his book The Man Who Created the Toyota Production System: The Fight of Taiichi Ohno (1988): "In 1950, Toyota was on the brink of bankruptcy due to labor disputes and financial collapse.

Toyota Motor Co Vice President Taiichi Ohno speaks during the Asahi

Toyota Motor Corporation's vehicle production system is a way of making things that is sometimes referred to as a "lean manufacturing system," or a "Just-in-Time (JIT) system," and has come to be well known and studied worldwide.

Taiichi Ohno Interview Video Footage Gemba Academy

FUNDAMENTALS Ohno's Method Creating a survival work culture. Jinichiro Nakane and Robert W. Hall T he legacy of the late Taiichi Ohno, father of the Toyota Production System (TPS), is much larger than the system's techniques, none of which he is known to have invented himself.

Toyotismo historia, características, ventajas y desventajas

Taiichi Ohno (1912 - 1990) was a leader in industrial engineering and is well known as the creator of the Toyota Production System, which in turn inspired the Lean theory and stemmed a wide range of Quality Improvement processes. We're going to be looking into his inventions and how his thinking helped shape Quality Improvement in healthcare.

Taiichi Ohno Hero of the Toyota Production System

Taiichi Ohno (1912-1990) was a prominent Japanese businessman. He is most famous for being the creator of the revolutionary Toyota Production System, which was later called Lean Manufacturing in the United States.

DRIVE Legend Taiichi Ohno 19121990, ο άνθρωπος που σκεφτόταν ανάποδα

Taiichi Ohno 's success of TPS development (Daily Improvements, Good Thinking and Good Products) within Toyota was spread to some extent by the telling of his story in books and articles translated into English. He was a great originator of new ideas, combined with a unique leadership style. Taiichi Ohno had the ability to identify the best.

A Collection of Quotes from Taiichi Ohno [Download PDF]

Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. [3] The system takes its name from the cards that track production within a factory. Kanban is also known as the Toyota nameplate system in the automotive industry.

6 Taiichi Ohno. (From public domain.) Download Scientific Diagram

Taiichi Ohno, a self-taught engineer who developed the manufacturing system that helped make the Toyota Motor Company one of the most powerful automobile producers in the world, died of heart.

Historia y biografía de Taiichi Ohno

Taiichi Ohno, popularly known as the pioneer of the Toyota Production System was born in Dalian, China in 1912. He graduated from the Nagoya Technical High School in Japan and joined Toyoda Spinning in 1932. He joined the Toyota Motor Company as a shop-floor supervisor in the year 1943 and rose to the position of an executive.